More strong drilling results to feed into coming resource update

Chibougamau Copper-Gold Project, Canada

/EIN News/ -- Results such as 4.4% CuEq over 9.1m at the Project’s flagship Corner Bay deposit; These follow the recent high-grade results at the nearby Golden Eye prospect

HIGHLIGHTS:

-

Latest infill results from Corner Bay demonstrate continuous high-grade mineralisation:

-

9.1m @ 4.4% CuEq (4.1% Cu, 0.3g/t Au & 14.4g/t Ag) (CB-25-118)

- Including 3.4m @ 7.6% CuEq (7.0% Cu, 0.4g/t Au & 24.9g/t Ag)

- 5.8m @ 5.3% CuEq (4.4% Cu, 0.8g/t Au & 28.1g/t Ag) (CB-25-122)

- 2.8m @ 5.0% CuEq (4.6% Cu, 0.4g/t Au & 14.6g/t Ag) (CB-25-119)

- 2.8m @ 4.1% CuEq (3.8% Cu, 0.2g/t Au & 16.3g/t Ag) (CB-25-120)

-

9.1m @ 4.4% CuEq (4.1% Cu, 0.3g/t Au & 14.4g/t Ag) (CB-25-118)

- These results highlight the strong potential to grow the Indicated Resource as part of the upcoming Mineral Resource update on the Chibougamau Project (the “Project”), which is scheduled for completion in the September quarter

- The current Corner Bay Indicated Resource is 2.7Mt at 2.9% CuEq and the Inferred Resource is 5.9Mt at 3.6% CuEq1

- Infill drilling is almost complete on the shallowest parts of the Corner Bay deposit; this area is expected to help underpin the early part of any production schedule at the Project

- The Corner Bay results follow the recently announced high-grade assays from the Golden Eye prospect (see ASX release dated 10 June 2025), where Cygnus expects to complete an initial resource to be included in the overall Project Mineral Resource update

- The current total Mineral Resource for the Project is comprised of Measured and Indicated Resources of 3.6Mt at 3% CuEq and Inferred Resources of 7.2Mt at 3.8% CuEq1

- Early engineering studies and permitting are underway

- The Project has a significant head start as a copper-gold development opportunity with well-established infrastructure including a 900,000tpa processing facility

|

Cygnus Executive Chairman David Southam said: “These latest results reinforce Cygnus’ understanding of the high-grade and continuous nature of the mineralisation at Corner Bay, and support our goal of upgrading more tonnes into the Indicated category. “This will enable us to assess the production potential and economic outlook for the Project with increased certainty. Given the resource growth potential with the high-grade drill results to date, the record gold prices and strong copper fundamentals, we are extremely keen to conduct updated studies. And the outlook is even better when you remember that this is a pure copper-gold story with potential silver credits and an existing processing plant in a tier-one location”.y with potential silver credits and an existing processing plant in a tier-one location”. |

TORONTO and PERTH, Australia, June 16, 2025 (GLOBE NEWSWIRE) -- Cygnus Metals Limited (ASX: CY5; TSXV: CYG; OTCQB: CYGGF) (“Cygnus” or the “Company”) is pleased to announce infill results from Corner Bay as the Company continues to execute its resource growth and conversion strategy at the Chibougamau Copper-Gold Project in Quebec.

The recent results are from infill drilling on the upper main vein, which will likely be scheduled into the early part of the potential production profile of the Project. Recent results include significant intersections of:

-

9.1m @ 4.4% CuEq (4.1% Cu, 0.3g/t Au & 14.4g/t Ag) (CB-25-118);

- Including 3.4m @ 7.6% CuEq (7.0% Cu, 0.4g/t Au & 24.9g/t Ag);

- 5.8m @ 5.3% CuEq (4.4% Cu, 0.8g/t Au & 28.1g/t Ag) (CB-25-122);

- 2.8m @ 5.0% CuEq (4.6% Cu, 0.4g/t Au & 14.6g/t Ag) (CB-25-119); and

-

2.8m @ 4.1% CuEq (3.8% Cu, 0.2g/t Au & 16.3g/t Ag) (CB-25-120).

These results will be incorporated in the upcoming Mineral Resource update as Cygnus seeks to convert Inferred Resources to Indicated Resources, with recent results reconciling well against the current block model. The Mineral Resource upgrade at Corner Bay is being completed in conjunction with new resource growth prospects such as Golden Eye. These are aimed at growing the current global resource, which stands at a Measured and Indicated Resource of 3.6Mt at 3% CuEq and Inferred Resources of 7.2Mt at 3.8% CuEq.1 The global Mineral Resource update for the Project is expected in Q3 2025, targeting both resource growth and conversion.

With work on the resource well advanced, Cygnus is also progressing the Project along the pathway to development, in line with its value creation strategy. This work includes early geotechnical studies across potential development sites as well as advancing long-lead permitting items. This work aims to streamline and accelerate future study work.

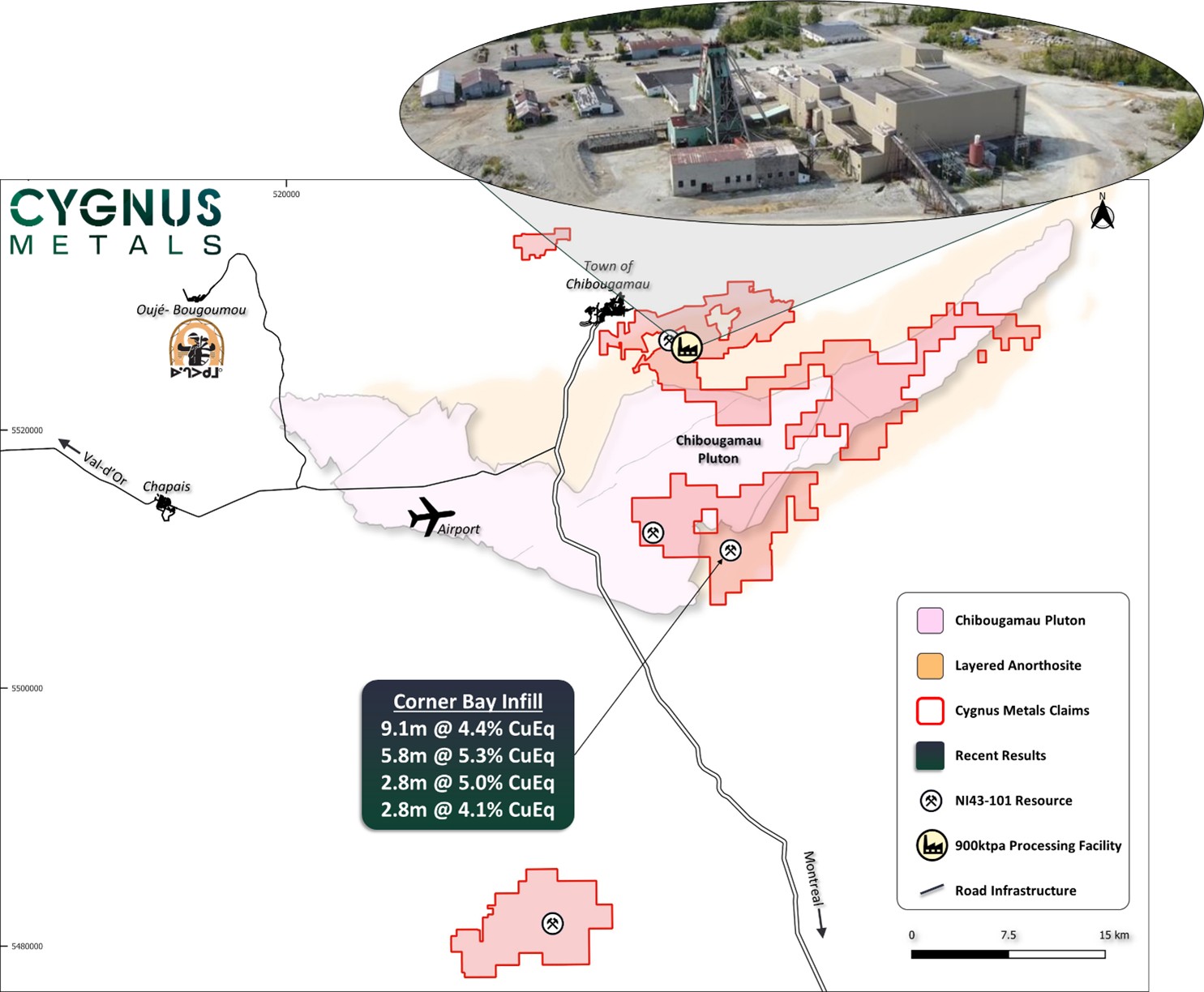

The Chibougamau area has well-established infrastructure giving the Project a significant head start as a copper-gold development opportunity. This infrastructure includes a 900,000tpa processing facility, local mining town, sealed highway, airport, regional rail infrastructure and 25kV hydro power to the processing site. Significantly, the Chibougamau processing facility is the only base metal processing facility within a 250km radius which includes a number of other advanced copper and gold projects.

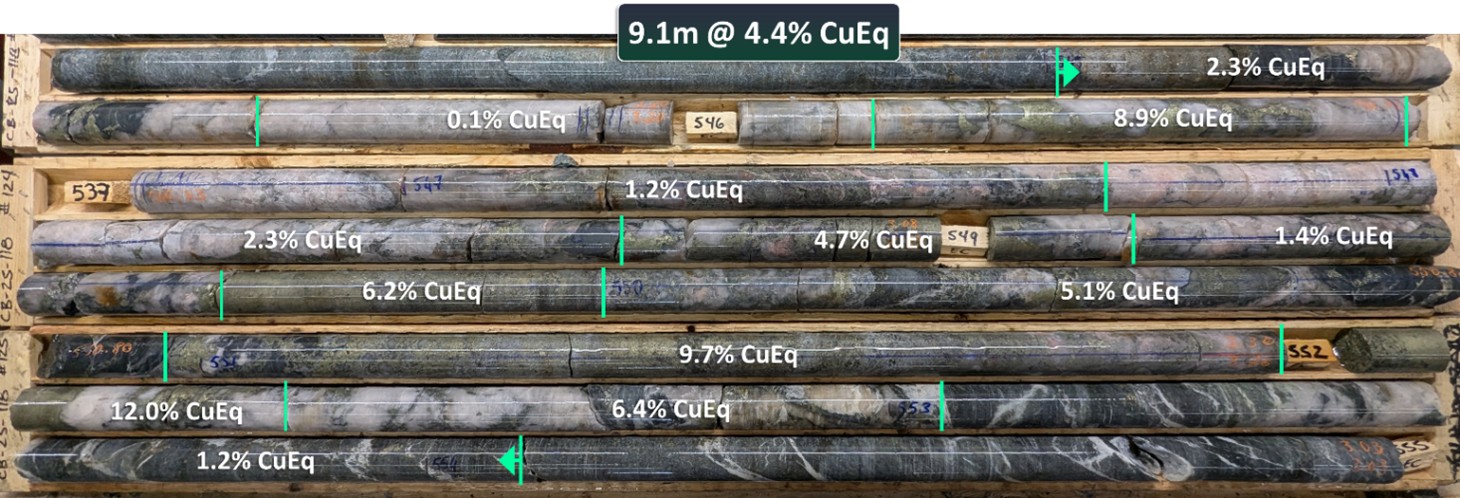

Figure 1: Drill core from CB-25-118 with 4.4% CuEq over 9.1m from 545m, including a high grade interval of 7.6% CuEq over 3.4m. Showing style and high-grade tenor of mineralisation at Corner Bay.

Figure 1: Drill core from CB-25-118 with 4.4% CuEq over 9.1m from 545m, including a high grade interval of 7.6% CuEq over 3.4m. Showing style and high-grade tenor of mineralisation at Corner Bay.

Ongoing Drilling

Cygnus is continuing its dual track strategy of resource growth and conversion. Work is in progress to generate additional drill targets surrounding the current high-grade copper-gold resource which can be targeted through low-risk brownfield exploration. Such work includes ongoing data compilation which is playing a significant role in unlocking this historic district.

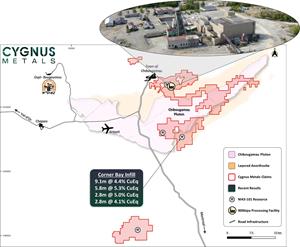

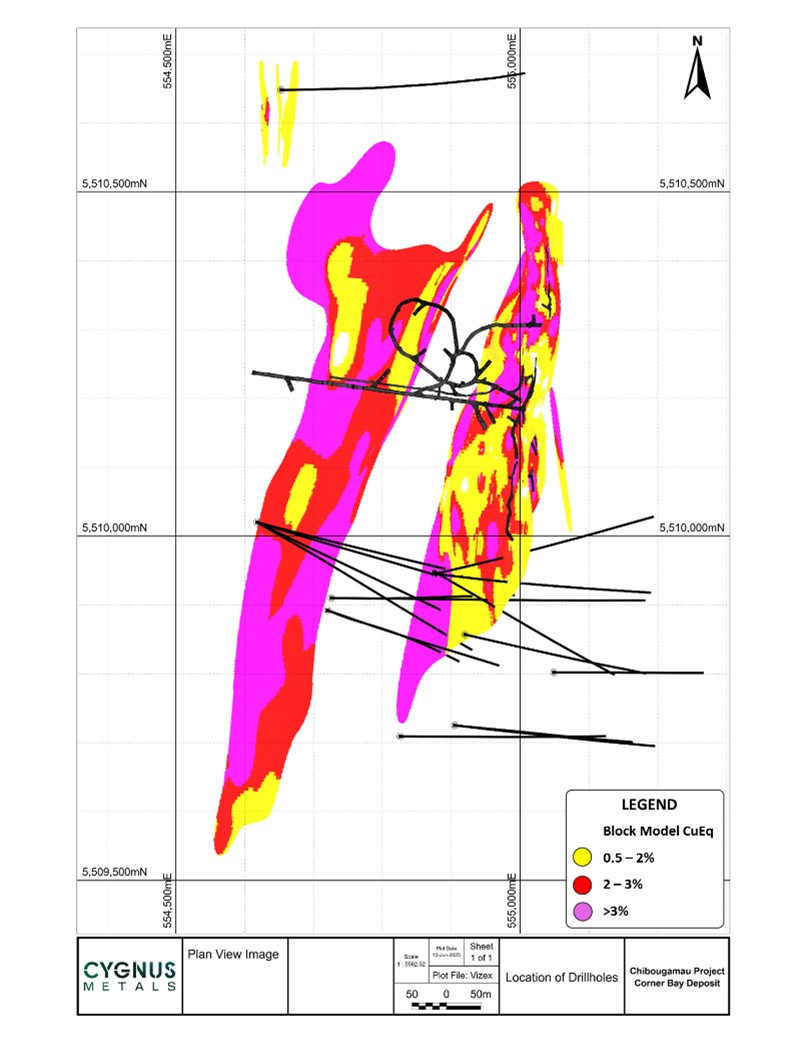

Figure 2: Location of Corner Bay recent infill drill results. Corner Bay is the primary resource at the Chibougamau Project with an Indicated Mineral Resource of 2.7Mt at 2.9% CuEq and Inferred Mineral Resource of 5.9Mt at 3.6% CuEq.1

This announcement has been authorised for release by the Board of Directors of Cygnus.

| David Southam | Ernest Mast | Media: |

| Executive Chair | President & Managing Director | Paul Armstrong |

| T: +61 8 6118 1627 | T: +1 647 921 0501 | Read Corporate |

| E: info@cygnusmetals.com | E: info@cygnusmetals.com | T: +61 8 9388 1474 |

About Cygnus Metals

Cygnus Metals Limited (ASX: CY5, TSXV: CYG, OTCQB: CYGGF) is a diversified critical minerals exploration and development company with projects in Quebec, Canada and Western Australia. The Company is dedicated to advancing its Chibougamau Copper-Gold Project in Quebec with an aggressive exploration program to drive resource growth and develop a hub-and-spoke operation model with its centralised processing facility. In addition, Cygnus has quality lithium assets with significant exploration upside in the world-class James Bay district in Quebec, and REE and base metal projects in Western Australia. The Cygnus team has a proven track record of turning exploration success into production enterprises and creating shareholder value.

Forward Looking Statements

This release may contain certain forward-looking statements and projections regarding estimates, resources and reserves; planned production and operating costs profiles; planned capital requirements; and planned strategies and corporate objectives. Such forward looking statements/projections are estimates for discussion purposes only and should not be relied upon. They are not guarantees of future performance and involve known and unknown risks, uncertainties and other factors, many of which are beyond Cygnus’ control. Cygnus makes no representations and provides no warranties concerning the accuracy of the projections and disclaims any obligation to update or revise any forward-looking statements/projections based on new information, future events or otherwise except to the extent required by applicable laws. While the information contained in this release has been prepared in good faith, neither Cygnus or any of its directors, officers, agents, employees or advisors give any representation or warranty, express or implied, as to the fairness, accuracy, completeness or correctness of the information, opinions and conclusions contained in this release. Accordingly, to the maximum extent permitted by law, none of Cygnus, its directors, employees or agents, advisers, nor any other person accepts any liability whether direct or indirect, express or limited, contractual, tortuous, statutory or otherwise, in respect of the accuracy or completeness of the information or for any of the opinions contained in this release or for any errors, omissions or misstatements or for any loss, howsoever arising, from the use of this release.

End Notes

- The estimate of mineralisation at the Chibougamau Project is a foreign estimate prepared in accordance with CIM Standards. A competent person has not done sufficient work to classify the foreign estimate as a mineral resource in accordance with the JORC Code, and it is uncertain whether further evaluation and exploration will result in an estimate reportable under the JORC Code. Refer to Appendix C for a breakdown of the Foreign Mineral Resource Estimate.

Qualified Persons and Compliance Statements

The scientific and technical information in this announcement has been reviewed and approved by Mr Louis Beaupre, the Quebec Exploration Manager of Cygnus, a “qualified person” as defined in National Instrument 43-101 – Standards of Disclosure for Mineral Projects. The Exploration Results disclosed in this announcement are also based on and fairly represent information and supporting documentation compiled by Mr Beaupre. Mr Beaupre holds options in Cygnus. Mr Beaupre is a member of the Ordre des ingenieurs du Quebec (P. Eng.), a Registered Overseas Professional Organisation as defined in the ASX Listing Rules, and has sufficient experience which is relevant to the style of mineralisation and type of deposits under consideration and to the activity which has been undertaken to qualify as a Competent Person as defined in the 2012 Edition of the “Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves”. Mr Beaupre consents to the inclusion in this release of the matters based on the information in the form and context in which they appear.

The Company first announced the foreign estimate of mineralisation for the Chibougamau Project on 15 October 2024. The Company confirms that the supporting information included in the original announcement continues to apply and has not materially changed, notwithstanding the clarification announcement released by Cygnus on 28 January 2025 (“Clarification”). Cygnus confirms that (notwithstanding the Clarification) it is not aware of any new information or data that materially affects the information included in the original announcement and that all material assumptions and technical parameters underpinning the estimates in the original announcement continue to apply and have not materially changed. Cygnus confirms that it is not in possession of any new information or data that materially impacts on the reliability of the estimates or Cygnus’ ability to verify the foreign estimates as mineral resources in accordance with the JORC Code. The Company confirms that the form and context in which the Competent Persons’ findings are presented have not been materially modified from the original market announcement.

The information in this announcement that relates to previously reported Exploration Results at the Company’s projects has been previously released by Cygnus in ASX Announcements as noted in the text and End Notes. Cygnus is not aware of any new information or data that materially affects the information in these announcements. The Company confirms that the form and context in which the Competent Persons’ findings are presented have not been materially modified from the original market announcements.

Individual grades for the metals included in the metal equivalents calculation for the foreign estimate are in Appendix C of this release. Metal equivalents for the foreign estimate of mineralisation have been calculated at a copper price of US$8,750/t, gold price of US$2,350/oz, with copper equivalents calculated based on the formula CuEq (%) = Cu(%) + (Au (g/t) x 0.77258). Individual grades for the metals included in the metal equivalents calculation for the exploration results are in Appendices A and B of this release. Metal equivalents for exploration results have been calculated at a copper price of US$8,750/t, gold price of US$2,350/oz and silver price of US$25/oz. Copper equivalents are calculated based on the formula CuEq(%) = Cu(%) + (Au(g/t) x 0.77258)+(Ag(g/t) x 0.00822). Gold equivalents are calculated based on the formula AuEq(g/t) = Au(g/t) +(Cu(%) x 1.29436)+(Ag(g/t) x 0.01064). Metallurgical recovery factors have been applied to the metal equivalents calculations, with copper metallurgical recovery assumed at 95% and precious metal (gold and silver) metallurgical recovery assumed at 85% based upon historical production at the Chibougamau Processing Facility, and the metallurgical results contained in Cygnus’ announcement dated 28 January 2025. It is the Company’s view that all elements in the metal equivalents calculations in respect of the foreign estimate and exploration results have a reasonable potential to be recovered and sold.

Neither TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

APPENDIX A – Significant Intersections from Infill Drilling

Coordinates given in UTM NAD83 (Zone 18). Intercept lengths may not add up due to rounding to the appropriate reporting precision. Significant intersections reported above 1% CuEq over widths of greater than 1m. True width estimated to be 80% of downhole thickness.

| Hole ID | X | Y | Z | Azi | Dip | Depth | From (m) | To (m) | Interval (m) | Cu (%) | Au (g/t) | Ag (g/t) | CuEq (%) |

| CB-25-108 | 554726 | 5509910 | 398 | 90 | -47 | 660 | 337.3 | 339.7 | 2.4 | 2.9 | 0.3 | 10.3 | 3.2 |

| & | 395.6 | 396.5 | 0.8 | 5.1 | 0.3 | 18.4 | 5.5 | ||||||

| & | 472.9 | 475.3 | 2.4 | 2.3 | 0.2 | 7.7 | 2.5 | ||||||

| CB-25-109 | 554876 | 5509948 | 400 | 77 | -54 | 525 | 184.7 | 186.8 | 2.1 | 3.1 | 0.2 | 13.0 | 3.3 |

| CB-25-117 | 554721 | 5509892 | 401 | 108 | -63 | 558 | 457.5 | 460.0 | 2.5 | 4.0 | 0.1 | 11.7 | 4.1 |

| CB-25-118 | 554721 | 5509892 | 401 | 112 | -71 | 648 | 545.0 | 554.1 | 9.1 | 4.1 | 0.3 | 14.4 | 4.4 |

| Including | 549.6 | 553.1 | 3.4 | 7.0 | 0.4 | 24.9 | 7.6 | ||||||

| CB-25-119 | 554618 | 5510020 | 394 | 119 | -57 | 661 | 573.3 | 576.1 | 2.8 | 4.6 | 0.4 | 14.6 | 5.0 |

| CB-25-120 | 554618 | 5510020 | 394 | 108 | -66 | 657 | 626.0 | 628.8 | 2.8 | 3.8 | 0.2 | 16.3 | 4.1 |

| CB-25-121 | 554618 | 5510020 | 394 | 117 | -63 | 659 | 618.2 | 620.3 | 2.0 | 1.9 | 0.3 | 8.8 | 2.2 |

| CB-25-122 | 554618 | 5510020 | 394 | 105 | -62 | 633 | 583.8 | 589.5 | 5.8 | 4.4 | 0.8 | 28.1 | 5.3 |

APPENDIX B – Other Intersections from Exploration Drilling around Corner Bay

Coordinates given in UTM NAD83 (Zone 18). Intercept lengths may not add up due to rounding to the appropriate reporting precision. Significant intersections reported above 1% CuEq over widths of greater than 1m. True width estimated to be 80% of downhole thickness. Drill holes were a mix of infill and step outs. All infill holes hit mineralization.

| Hole ID | X | Y | Z | Azi | Dip | Depth | From (m) | To (m) | Interval (m) | Cu (%) | Au (g/t) | Ag (g/t) | CuEq (%) |

| CB-24-101 | 554757 | 5511009 | 389 | 80 | -50 | 525 | No Significant Intercept | ||||||

| CB-24-102 | 554653 | 5510648 | 381 | 90 | -67 | 954 | No Significant Intercept | ||||||

| CB-24-107 | 554726 | 5509910 | 400 | 91 | -57 | 480 | 458.6 | 460.0 | 1.4 | 2.1 | 0.2 | 6.6 | 2.3 |

| CB-25-110 | 554876 | 5509948 | 400 | 97 | -48 | 474 | 264.8 | 267.0 | 2.2 | 1.8 | 0.1 | 5.2 | 1.9 |

| CB-25-111 | 554920 | 5509857 | 400 | 103 | -58 | 504 | 441.8 | 444.2 | 2.4 | 4.0 | 0.3 | 12.2 | 4.3 |

| CB-25-112 | 555049 | 5509802 | 400 | 90 | -45 | 303 | 244.7 | 247.4 | 2.7 | 1.1 | 0.0 | 4.3 | 1.1 |

| CB-25-113 | 554905 | 5509725 | 400 | 96 | -52 | 471 | No Significant Intercept | ||||||

| CB-25-114 | 554905 | 5509725 | 400 | 96 | -63 | 564 | No Significant Intercept | ||||||

| CB-25-115 | 554876 | 5509948 | 400 | 120 | -61 | 621 | 313.0 | 314.8 | 1.9 | 1.6 | 0.1 | 6.1 | 1.7 |

| 333.2 | 335.0 | 1.8 | 4.5 | 0.1 | 16.3 | 4.7 | |||||||

| 583.0 | 586.5 | 3.5 | 0.9 | 0.1 | 2.2 | 1.0 | |||||||

| CB-25-116 | 554826 | 5509709 | 397 | 90 | -64 | 645 | 535.0 | 537.9 | 2.9 | 0.8 | 0.1 | 2.4 | 0.9 |

| 606.3 | 607.5 | 1.2 | 1.3 | 0.1 | 3.9 | 1.5 | |||||||

APPENDIX C – Chibougamau Copper-Gold Project – Foreign Mineral Resource Estimate Disclosures as at 30 March 2022

| Deposit | Category | Tonnes (k) | Cu Grade (%) | Au Grade (g/t) | Cu Metal (kt) | Au Metal (koz) | CuEq Grade (%) |

| Corner Bay (2022) |

Indicated | 2,700 | 2.7 | 0.3 | 71 | 22 | 2.9 |

| Inferred | 5,900 | 3.4 | 0.3 | 201 | 51 | 3.6 | |

| Devlin (2022) |

Measured | 120 | 2.7 | 0.3 | 3 | 1 | 2.9 |

| Indicated | 660 | 2.1 | 0.2 | 14 | 4 | 2.3 | |

| Measured & Indicated | 780 | 2.2 | 0.2 | 17 | 5 | 2.4 | |

| Inferred | 480 | 1.8 | 0.2 | 9 | 3 | 2.0 | |

| Joe Mann (2022) | Inferred | 610 | 0.2 | 6.8 | 1 | 133 | 5.5 |

| Cedar Bay (2018) |

Indicated | 130 | 1.6 | 9.4 | 2 | 39 | 8.9 |

| Inferred | 230 | 2.1 | 8.3 | 5 | 61 | 8.5 | |

|

Total |

Measured & Indicated | 3,600 | 2.5 | 0.6 | 90 | 66 | 3.0 |

| Inferred | 7,200 | 3.0 | 1.1 | 216 | 248 | 3.8 |

APPENDIX D – 2012 JORC Table 1

Section 1 Sampling Techniques and Data

| Criteria | JORC Code explanation | Commentary |

|

Sampling techniques |

Nature and quality of sampling (eg cut channels, random chips, or specific specialised industry standard measurement tools appropriate to the minerals under investigation, such as down hole gamma sondes, or handheld XRF instruments, etc). These examples should not be taken as limiting the broad meaning of sampling. |

|

| Include reference to measures taken to ensure sample representativity and the appropriate calibration of any measurement tools or systems used. |

|

|

|

Aspects of the determination of mineralisation that are Material to the Public Report. In cases where ‘industry standard’ work has been done this would be relatively simple (eg ‘reverse circulation drilling was used to obtain 1 m samples from which 3 kg was pulverised to produce a 30 g charge for fire assay’). In other cases more explanation may be required, such as where there is coarse gold that has inherent sampling problems. Unusual commodities or mineralisation types (eg submarine nodules) may warrant disclosure of detailed information. |

|

|

| Drilling techniques | Drill type (eg core, reverse circulation, open-hole hammer, rotary air blast, auger, Bangka, sonic, etc) and details (eg core diameter, triple or standard tube, depth of diamond tails, face-sampling bit or other type, whether core is oriented and if so, by what method, etc). |

|

| Drill sample recovery |

Method of recording and assessing core and chip sample recoveries and results assessed. Measures taken to maximise sample recovery and ensure representative nature of the samples. Whether a relationship exists between sample recovery and grade and whether sample bias may have occurred due to preferential loss/gain of fine/coarse material. |

|

|

Logging |

Whether core and chip samples have been geologically and geotechnically logged to a level of detail to support appropriate Mineral Resource estimation, mining studies and metallurgical studies. |

|

| Whether logging is qualitative or quantitative in nature. Core (or costean, channel, etc) photography. |

|

|

| The total length and percentage of the relevant intersections logged. |

|

|

| Sub-sampling techniques and sample preparation |

If core, whether cut or sawn and whether quarter, half or all core taken. If non-core, whether riffled, tube sampled, rotary split, etc and whether sampled wet or dry. For all sample types, the nature, quality and appropriateness of the sample preparation technique. Quality control procedures adopted for all sub-sampling stages to maximise representivity of samples. Measures taken to ensure that the sampling is representative of the in-situ material collected, including for instance results for field duplicate/second-half sampling. Whether sample sizes are appropriate to the grain size of the material being sampled. |

|

|

Quality of assay data and laboratory tests |

The nature, quality and appropriateness of the assaying and laboratory procedures used and whether the technique is considered partial or total. |

|

| For geophysical tools, spectrometers, handheld XRF instruments, etc, the parameters used in determining the analysis including instrument make and model, reading times, calibrations factors applied and their derivation, etc. |

|

|

| Nature of quality control procedures adopted (eg standards, blanks, duplicates, external laboratory checks) and whether acceptable levels of accuracy (i.e. lack of bias) and precision have been established. |

|

|

|

Verification of sampling and assaying |

The verification of significant intersections by either independent or alternative company personnel. |

|

| The use of twinned holes. |

|

|

| Documentation of primary data, data entry procedures, data verification, data storage (physical and electronic) protocols. |

|

|

| Discuss any adjustment to assay data. |

|

|

|

Location of data points |

Accuracy and quality of surveys used to locate drill holes (collar and down-hole surveys), trenches, mine workings and other locations used in Mineral Resource estimation. |

|

| Specification of the grid system used. |

|

|

| Quality and adequacy of topographic control. |

|

|

|

Data spacing and distribution |

Data spacing for reporting of Exploration Results. |

|

| Whether the data spacing and distribution is sufficient to establish the degree of geological and grade continuity appropriate for the Mineral Resource and Ore Reserve estimation procedure(s) and classifications applied. |

|

|

| Whether sample compositing has been applied. |

|

|

|

Orientation of data in relation to geological structure |

Whether the orientation of sampling achieves unbiased sampling of possible structures and the extent to which this is known, considering the deposit type. |

|

| If the relationship between the drilling orientation and the orientation of key mineralised structures is considered to have introduced a sampling bias, this should be assessed and reported if material. |

|

|

| Sample security | The measures taken to ensure sample security. |

|

| Audits or reviews | The results of any audits or reviews of sampling techniques and data. |

|

Section 2 Reporting of Exploration Results

(Criteria listed in the preceding section also apply to this section.)

| Criteria | JORC Code Explanation | Commentary |

|

Mineral tenement and land tenure status |

Type, reference name/number, location and ownership including agreements or material issues with third parties such as joint ventures, partnerships, overriding royalties, native title interests, historical sites, wilderness or national park and environmental settings. |

|

| The security of the tenure held at the time of reporting along with any known impediments to obtaining a licence to operate in the area. |

|

|

| Exploration done by other parties | Acknowledgment and appraisal of exploration by other parties. |

|

| Geology | Deposit type, geological setting and style of mineralisation. |

|

| Drill hole Information |

A summary of all information material to the understanding of the exploration results including a tabulation of the following information for all Material drill holes:

|

|

|

Data aggregation methods |

In reporting Exploration Results, weighting averaging techniques, maximum and/or minimum grade truncations (eg cutting of high grades) and cut-off grades are usually Material and should be stated. |

|

| Where aggregate intercepts incorporate short lengths of high-grade results and longer lengths of low-grade results, the procedure used for such aggregation should be stated and some typical examples of such aggregations should be shown in detail. |

|

|

| The assumptions used for any reporting of metal equivalent values should be clearly stated. |

|

|

| Relationship between mineralisation widths and intercept lengths |

These relationships are particularly important in the reporting of Exploration Results. If the geometry of the mineralisation with respect to the drill hole angle is known, its nature should be reported. If it is not known and only the down hole lengths are reported, there should be a clear statement to this effect (eg ‘down hole length, true width not known’). |

|

| Diagrams | Appropriate maps and sections (with scales) and tabulations of intercepts should be included for any significant discovery being reported. These should include,but not be limited to a plan view of drill hole collar locations and appropriate sectional views. |

|

| Balanced reporting | Where comprehensive reporting of all Exploration Results is not practicable, representative reporting of both low and high grades and/or widths should be practiced to avoid misleading reporting of Exploration Results. |

|

| Other substantive exploration data | Other exploration data, if meaningful and material, should be reported including (but not limited to): geological observations; geophysical survey results; geochemical survey results; bulk samples – size and method of treatment; metallurgical test results; bulk density, groundwater, geotechnical and rock characteristics; potential deleterious or contaminating substances. |

|

| Further work |

The nature and scale of planned further work (eg tests for lateral extensions or depth extensions or large-scale step-out drilling). Diagrams clearly highlighting the areas of possible extensions, including the main geological interpretations and future drilling areas, provided this information is not commercially sensitive. |

|

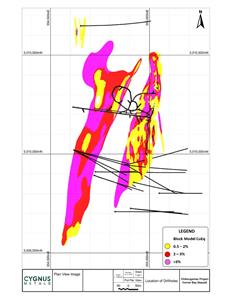

Figure 3: Plan view of recent infill drilling at Corner Bay

Figures accompanying this announcement are available at:

https://www.globenewswire.com/NewsRoom/AttachmentNg/4a1656b2-21ec-41fc-824f-44a6c13a0dcd

https://www.globenewswire.com/NewsRoom/AttachmentNg/3bc5086b-2cca-47b4-a3fa-4c5c98a5e927

https://www.globenewswire.com/NewsRoom/AttachmentNg/f6a8bfc7-c71e-4da3-97a8-1ddec57cb306

_____________

1 The estimate of mineralisation at the Chibougamau Project is a foreign estimate prepared in accordance with CIM Standards and is not reported in accordance with the JORC Code. A competent person has not done sufficient work to classify the foreign estimate as a mineral resource in accordance with the JORC Code, and it is uncertain that following evaluation and/or further exploration work that the foreign estimate will be able to be reported as a mineral resource or ore reserve in accordance with the JORC Code.

Plan view of recent infill drilling at Corner Bay

Figure 3. Plan view of recent infill drilling at Corner Bay

Drill core from CB-25-118 with 4.4% CuEq over 9.1m from 545m, including a high grade interval of 7.6% CuEq over 3.4m. Showing style and high-grade tenor of mineralisation at Corner Bay.

Figure 1: Drill core from CB-25-118 with 4.4% CuEq over 9.1m from 545m, including a high grade interval of 7.6% CuEq over 3.4m. Showing style and high-grade tenor of mineralisation at Corner Bay.

Location of Corner Bay recent infill drill results. Corner Bay is the primary resource at the Chibougamau Project with an Indicated Mineral Resource of 2.7Mt at 2.9% CuEq and Inferred Mineral Resource of 5.9Mt at 3.6% CuEq.1

Figure 2: Location of Corner Bay recent infill drill results. Corner Bay is the primary resource at the Chibougamau Project with an Indicated Mineral Resource of 2.7Mt at 2.9% CuEq and Inferred Mineral Resource of 5.9Mt at 3.6% CuEq.1

Distribution channels: Media, Advertising & PR, Mining Industry ...

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release